Socket Welding for Pipeline Connection

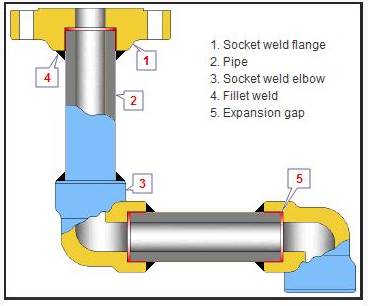

Socket Welding Connection is a common way of pipeline connection.

As the name suggests that socket into another end and weld. And it will use fillet weld for connection.

Generally it is common in petrochemical industry, and other application areas are steel mill, power plant, shipyard and so on.

Mainly processing the fittings to be socket directly. Like Socket Welding Valve, Socket Welding Elbow, Socket Welding Flange, Socket Welding Tee, Socket Welding Coupling and Pipeline Accessories. Finally it will be convenient for other equipment using after pipeline connect with them.

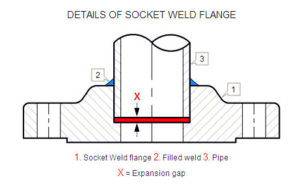

Socket Weld Flange Drawing

The frequently conditions that adopt socket welding connection is small diameter pipeline. The largest diameter is DN100 ( 4 Inch) in the standard. Most are below DN50 ( 2 Inch). Also use DN65, DN80, DN100 but less. Beucase it will increase more cost than butt weld fittings.

While the fittings size is below DN50, the butt weld fittings will be more difficult for welding with pipeline. Not easy as socket welding. The Non-destructive Test for Socket weld are Magnetic Test (MT) and Permeate Test (PT).

The advantage of socket weld are no need to be beveled and the pipe will not opposite to the wrong side after welding.

Latest News

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...  29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...

29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...  19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....

19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....